Growing Pharmaceutical Manufacturing with Synthetic Biology

The power of biology to make medicine is a big part of why I got into this business. Today we're talking about synbio for manufacturing active pharmaceutical ingredients - APIs.

Transcript

If you study biology, or if you study medicine, there's a moment that comes, usually pretty early in your career. You'll have a professor talking about the R&D process, where new drugs come from, and they'll drop a fact on you like "50% of pharmaceuticals are derived from natural products."1

Sometimes the number is a little higher or a little lower, depending on exactly what they count as a natural product. But the impact is the same. Medicine is biology. Those little pills don't really look like nature, but the molecules inside them were evolved in plants, microbes, and other living things.

Then, if you're a synthetic biologist like me, there's another moment that comes later on, when you learn that the enzymes and metabolic pathways that produce those molecules are engineerable. That means we can use microbes to produce those medicines through fermentation. Rare and expensive natural products can be made by nature's cheapest and most common life forms.

It's a beautiful part of the story of modern biopharma. It almost sounds like utopian science fiction. Cheap, sustainable, abundant, locally produced medicines. Medicines that grow themselves.

If you work in the business of manufacturing Active Pharmaceutical Ingredients, APIs, you already know all this. You've also noticed that APIs are having a moment, and you might feel pretty seen right now. It turns out, the way we make medicines is kind of important.

Generic drugs have never been hotter. Supply chains have never been sexier. Governments want local sources of essential medicines and the key starting materials for making them2. Sustainability matters and synbio can help get us there. Bioproduction and green chemistry can reduce the carbon footprint of your supply chain, up to 50-90% in some cases3. Enzymatic synthesis can mean fewer solvents, fewer toxic metals, fewer byproducts, compared to traditional chemistry.

And finally: money. Generic API manufacturing, in particular, is usually pretty cost sensitive. Better bioproduction means lower cost of goods, which goes straight to the bottom line. Some of the APIs that could be out there, aren't, because the manufacturing costs are too high. So cutting those costs can be existential if we want to get those medicines off the shelf and into doctors' hands.

Here at Ginkgo Bioworks, we see you API manufacturers, and we want to help. We're a synthetic biology platform company. That means we don't manufacture our own APIs. We partner with you to develop your API products. We handle the DNA stuff - everything upstream of manufacturing. Better strains, better enzymes, better bioprocesses.

Generally speaking, we can help with

Synthetic APIs that use an enzyme somewhere in the synthesis (or you don't use an enzyme yet but you could).

Fermentation products are already made by microbial strains

Extracts that are currently collected from plants or other natural sources

For your synthetic APIs, we offer enzyme engineering for biocatalysis. We can discover and engineer enzymes to catalyze the key reactions. I'll give a quick example. Often in an enzyme engineering project, we're focused on the reaction rate. We want the most active possible enzyme. But for APIs the specificity can be even more important. Byproducts and side reactions have to get purified out, which is often a big driver of cost.

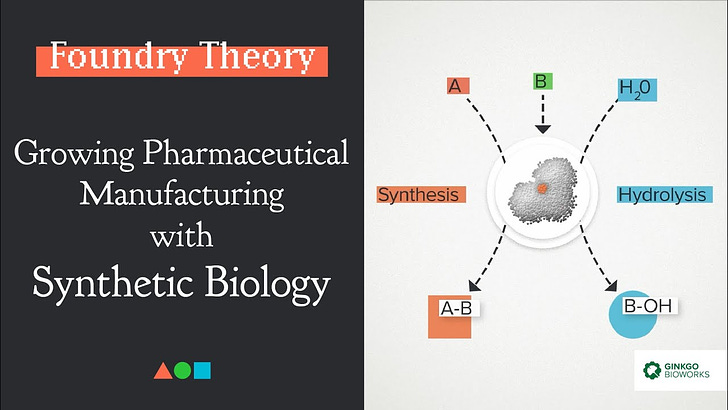

For this project we had a customer with an enzyme that was catalyzing both a synthesis reaction and a hydrolysis side reaction. We brought in our protein engineering team to design about 1100 variants of the enzyme. AI-guided design, all that good stuff. We built and tested them all in the foundry. The top performers had about twice the rate of product formation and half the byproduct. Overall a 5- or 6-fold improvement in performance.

For those APIs that are already produced with microbial fermentation, we do strain improvement. We've got the tech for genome editing, directed evolution or ultra-high throughput screening - the whole kit and caboodle. We recently did a project where we took a customer's existing strain, worked it up in the foundry, and turned around a 16% improvement in product yield in one round of engineering. Just as an example of what can be achieved quickly.

For APIs that come from plant extracts, we can do strain engineering to transfer a complete metabolic pathway into a microbial host. This is the kind of synthetic biology challenge we love here at Ginkgo.

We recently had a customer with a plant-derived API that they wanted to manufacture in microbes. It was a natural product derived from the terpene pathway, that absolutely classic source of cool bioactive molecules. We've worked with terpenes before so we had the foundation for how to make this pathway run in yeast. We added 7 additional enzymes to reach a key intermediate target.

This one required engineering cytochrome P450s, which can be tricky. It required navigating some existing patents. And it's not done yet. We're working on 14 more steps to do the complete pathway. But we got to this to proof-of-concept in 8 months because of the full stack of strain engineering capabilities here in the foundry.

Better enzymes, better strains, better bioprocesses. Upgrading your API manufacturing with biotech means more stable supply chains, lower environmental impact and yeah, it can save you money. Because money doesn't grow on trees. And APIs don't grow on trees. At least, not yet.

Newman DJ, Cragg GM. Natural products as sources of new drugs over the 30 years from 1981 to 2010. J Nat Prod. 2012 Mar 23;75(3):311-35. PMID: 22316239

A Bold Goal: Reshoring 25% Of Small Molecule API To The U.S. in 5 Years. The API Innovation Center.

Caring at Ginkgo: 2022 Sustainability Report.