The Time I Fought my Lab Robots and Lost

I love robots but they haven't always loved me back. Today we're talking about why scientists fight lab automation and how we could maybe all just get along.

Transcript

They always look so good. It's the blinky lights. The clean lines. You see a lab robot and it's easy to think: "this baby is going to solve all my R&D problems." So you bring it into your lab, and it's kind of mid. It's just ok. Or worse, you start fighting.

The person who bought the robot doesn't always see the reality of the scientists who use it. I've been on both sides of this and I know how it is when lab automation goes bad. Let me share a story from my pre-Ginkgo days.

I was doing some chemical genetics. I had about 1000 small-molecule drugs. I had about 100 microbial strains, each one with a different genetic background. I wanted to test every drug against every strain and measure the effect on a particular set of biomarkers. The idea was that this was going to help us figure out which genes are targeted by which drugs.

The details aren't that important, except to say the project looked like a lot of biotech R&D. There were a lot of tests to do: 100,000 possible combinations. Most of the operations were standard, so we knew they'd be easy to automate. Some of the work was custom and we knew it would need debugging.

We had 3 beautiful robots. Typical benchtop systems like you might find anywhere. An acoustic liquid handler to dispense libraries of drugs. A pipetting robot to dispense cultures of cells. A plate reader to perform the measurements. On paper, these machines can do all the core operations. We're good to go.

Well the first thing that goes wrong is that the robots don't actually do it all. They do their thing really well, but they don't connect upstream or downstream. Somebody has to defrost the stocks and load them on. Somebody has to carry the plates from robot to robot. The protocol becomes like an assembly line where the robots and humans are out of sync.

You know that episode of I Love Lucy where she's working in the chocolate factory and the chocolates are coming down the line too fast. It was exactly like that except we couldn't eat the samples. Any I Love Lucy fans out there? Classic episode.

The second thing is that these robots were not positioned with our work in mind and they're not easy to move. They're all in different rooms, on whatever benchtop they happened to get installed, and we humans have to work around that setup. There's all these externalities to manage that aren't technically part of the robot itself, so they weren't designed for. The reagent bottles. The waste streams. They have to go somewhere. You're playing Tetris with plasticware and biohazards.

And then there's the setup overhead. These machines are not easy to program. Every change needs to be tested and optimized. The breaking point came when we realized we had to add another robot to the workflow. We needed a centrifugation step between filling the plates and reading them. Well that room didn't have a centrifuge - it was down the hall. We're spending all this time schlepping samples around, babysitting robots and debugging them. You know what doesn't need debugging? The human hand. So we ended up doing a lot of those experiments with multichannel pipettes. Standing right next to a million dollars worth of robots.

Saddest thing you ever saw. I'm not proud of it. But I share my story to raise awareness about why R&D teams fight with lab automation. The robot looks great in the catalog, but the unfussy solution looks great in the real world at 4PM on a Friday. Scientists need flexibility as well as scale. Robots need to integrate easily to human operations and to other robots. Humans doing R&D are going to realize they forgot to add a centrifuge and they need to be able to reconfigure those connections quickly.

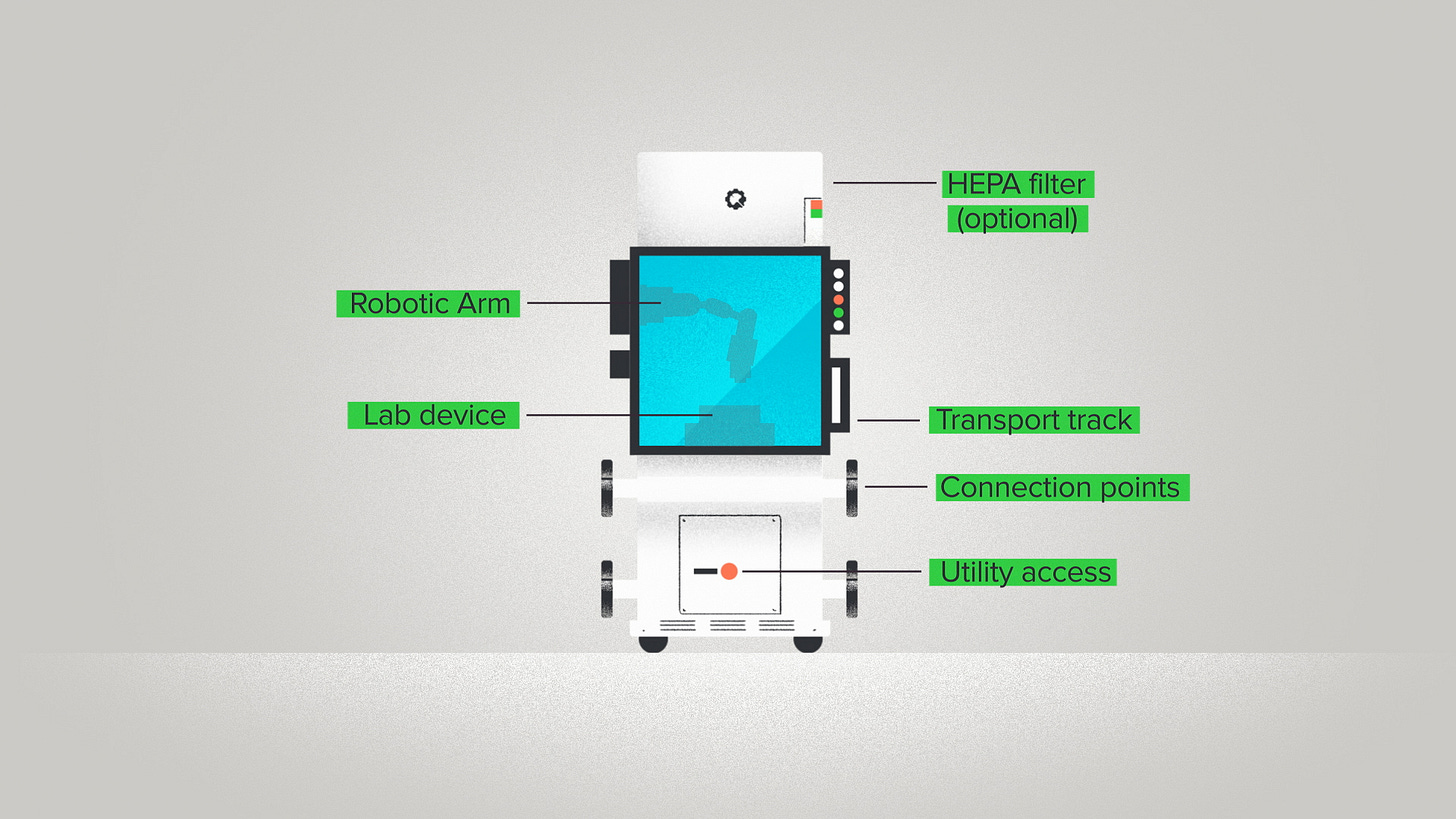

Hence - RACs: Reconfigurable Automation Carts. We developed these at Ginkgo as a way to make lab automation more versatile and more modular. They come in different sizes to fit standard benchtop robots. Each one includes a robotic arm for moving samples. There's an input port for electrical, air and data lines. You can add a HEPA filter to keep things sterile. There are quick connection points that make it easy to chain robots together into RAC systems.

RACs would have been a great solution for my automation experience from hell. An acoustic liquid handler, a pipetting robot, a plate reader, all running along a single rail. Oh, you need to add a centrifuge? It just slots right in.

What if you're not satisfied with 100,000 data points and you want to scale up the experiment even more? You can add additional robots to de-bottleneck whatever process is slowing you down and you don't need to re-engineer the whole automation line.

We've deployed RACs for workflows in drug discovery and seen 10x improvements in throughput. We've set them up for sample processing for next-gen sequencing and sped up the process by 60%. But the numbers don't really do it justice. The magic is seeing how fast a RAC system actually comes together on the shop floor. Large systems can go from storage to fully operational in days. I spent years in a lab and I can recall maybe 2 occasions when we moved a robot after it was installed. With RACs it takes minutes.

The shift here that matters for R&D is that we're getting closer to lab automation that "just works." On my darkest day, when I gave up on automation and resorted to manual pipetting, it was because I just needed to get things done. As a scientist, I wanted a flexible tool that I knew I could reconfigure quickly.

RACs get us closer to that ideal. This is what it will take to stop your scientists fighting your automation. The future state of biotech where human users are building workflows with the robots, instead of building workflows around the robots.

Learn more about RACs

Will Serber, Head of Automation, Presents RACs at the 2024 Ginkgo Ferment