A couple years ago I had an experience that changed the way I think about lab automation. I had a Ginkgo moment, if you like. Today we're talking about RACs - Reconfigurable Automation Carts.

Transcript

So I was taking a tour of the Ginkgo foundry. It was my first time. I'm looking around and feeling kind of impressed, but I'm trying to play it cool. I see a lot of robotics. Scientists using them. Loading on their cells. Pushing buttons. Collecting data. There's a lot going on, but what's the big picture?

Today, I get it. Automating biotech for flexibility and scale. Ginkgo is a therapeutic discovery platform. It's a wet lab data factory. Companies partner with Ginkgo because they want to do next-gen biotech R&D or because they want to buy experimental data. Ginkgo uses all this automation to deliver those R&D programs for our partners.

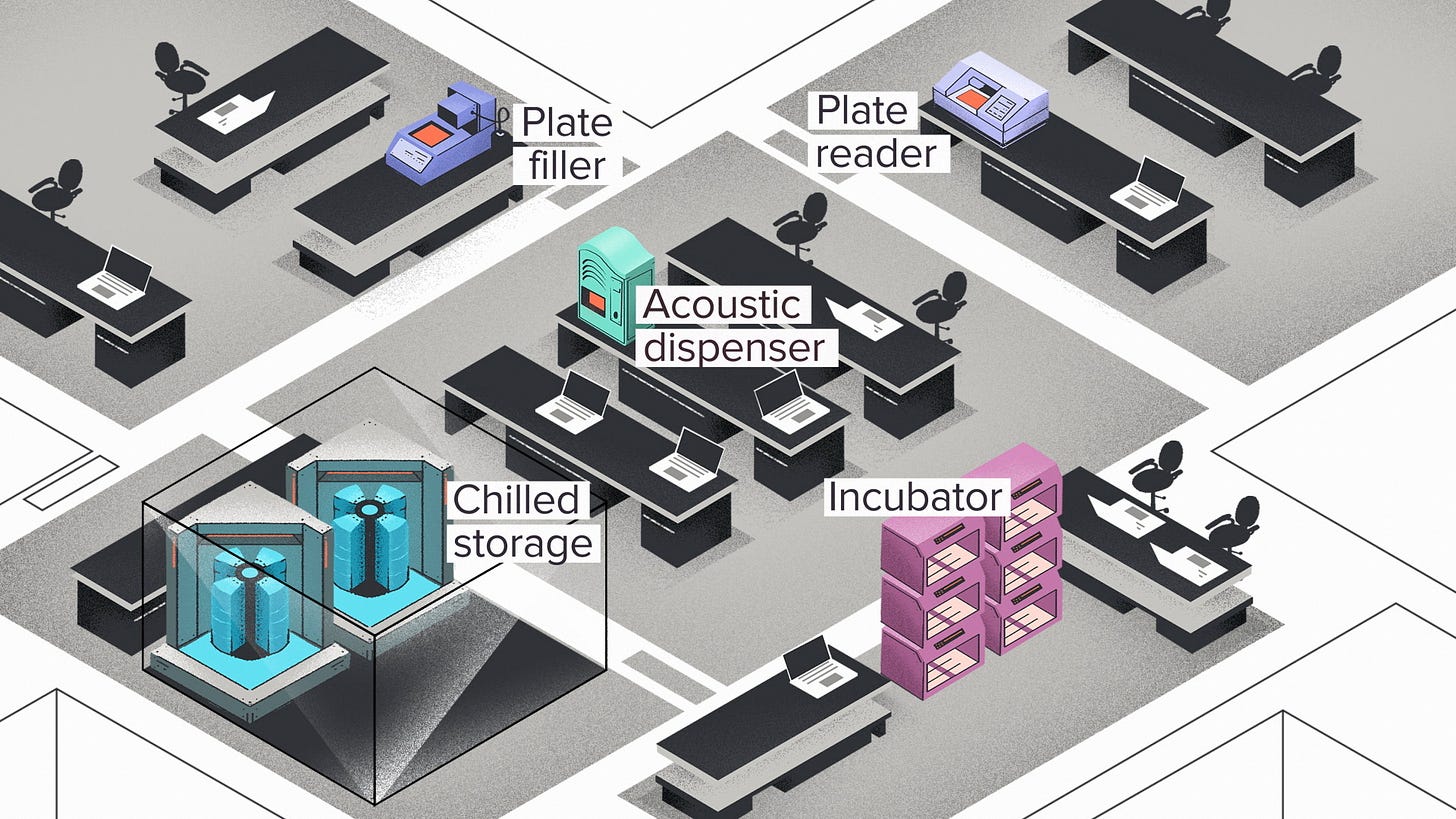

But back then I'm looking around like yeah, I know all about robots. I ran a small lab at the time and we had some pretty good kit. I've got plate fillers. I've got plate readers. I've got an acoustic liquid handler (pretty fancy). Modern labs have this stuff. No big deal for me.

So then my tour guide asks, how do you change out the robots in your workflow? And I hesitate, because I never really thought about it that way. In my experience, the robots were a fixed infrastructure. Human scientists move the samples around them and adjust their parameters. The details of a protocol can change every day, but changing a robot takes months. It's two different timescales, so, for me, it was two different thought processes.

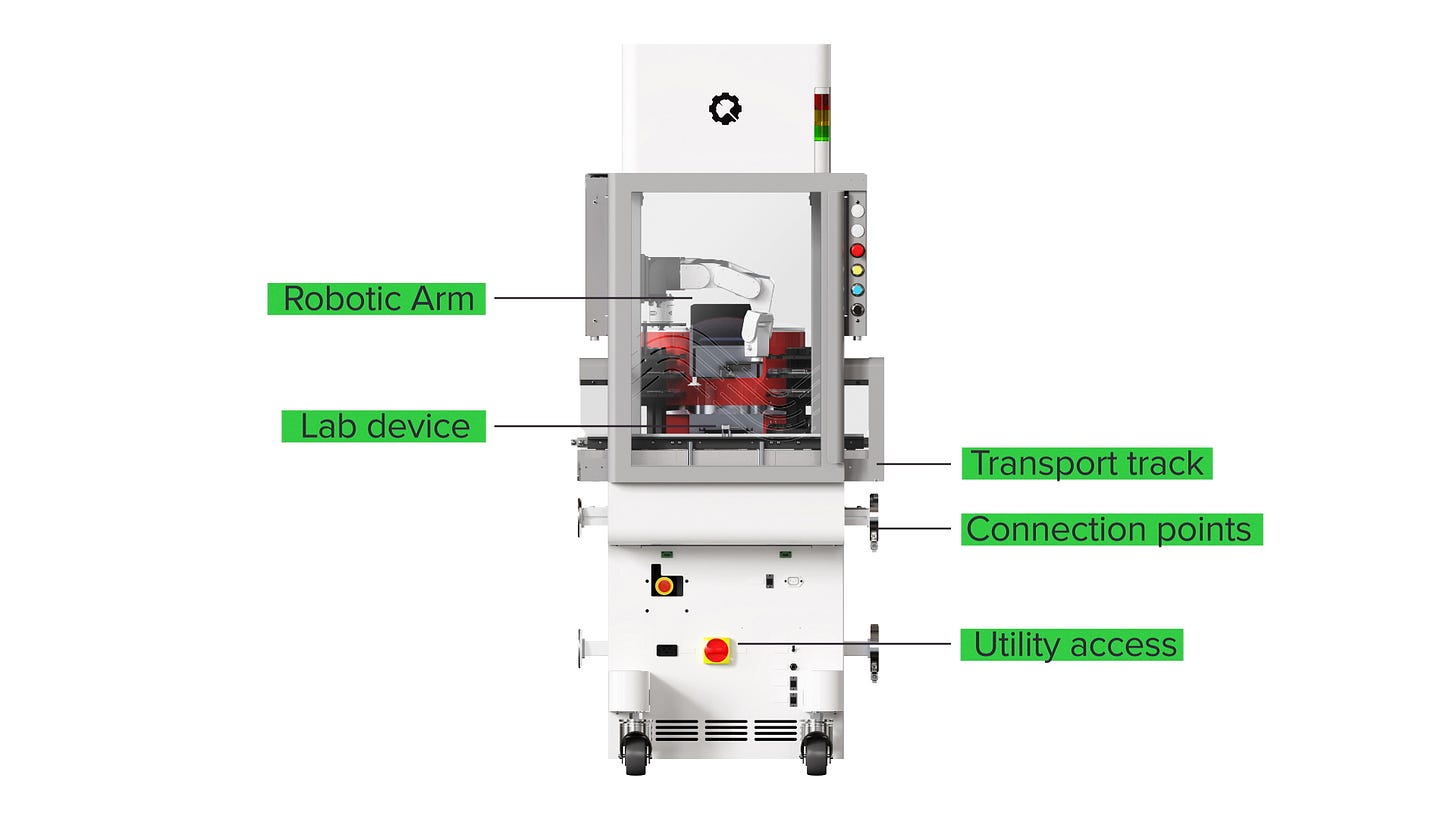

Then he says, "well for this system, we handle it like this." And he walks over to a robot. I think it was a plate sealer. And I see this thing is sitting on a cart with wheels. He rolls it across the room, slides it next to the other robots, attaches these clamp things on the side and the whole track just…aligns. Like the system was built that way.

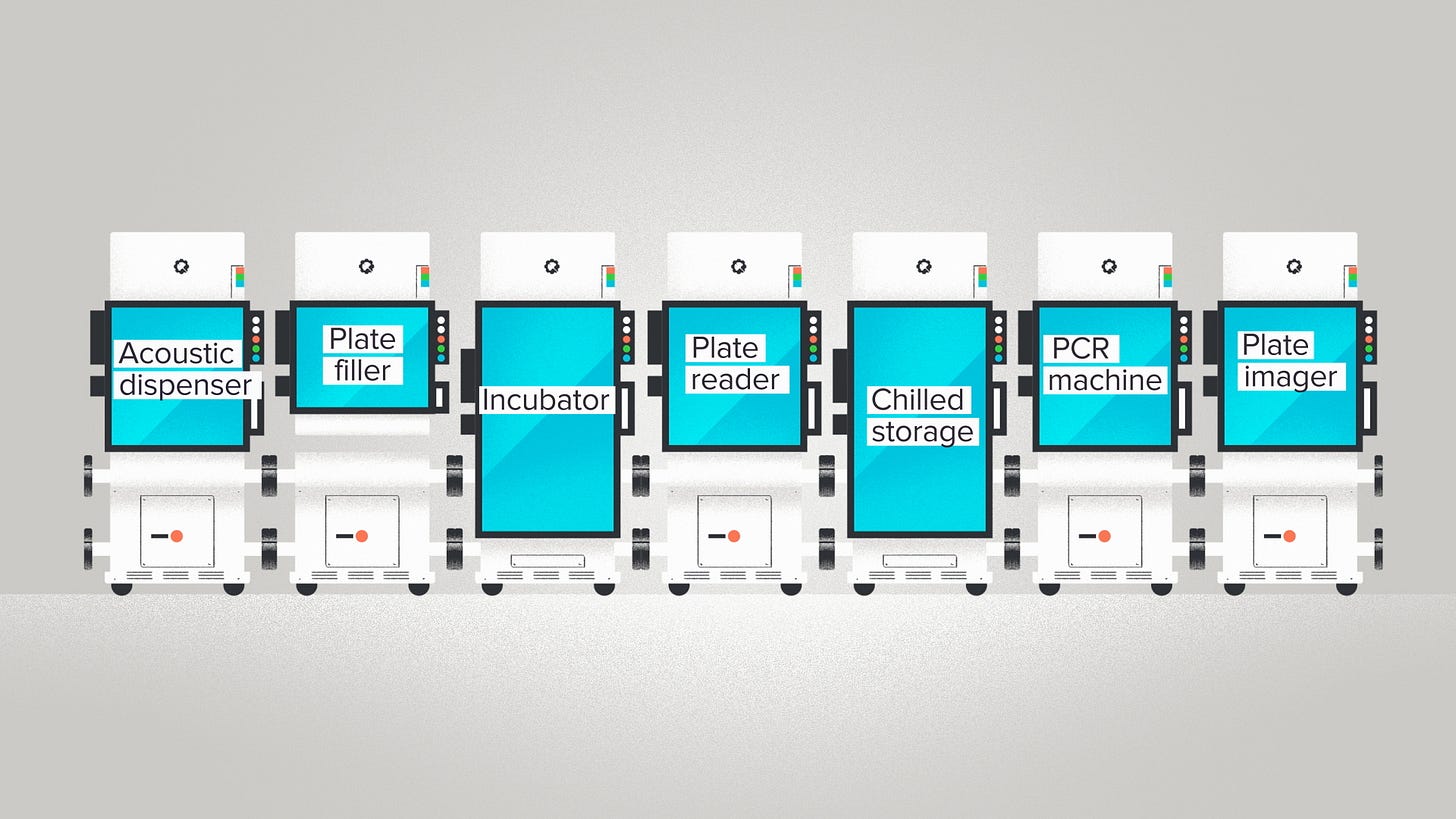

It blew my mind. It wasn't just the slick hardware. It was the modularity of the process. The plug and play nature of it. With one gesture, laboratory robotics went from being part of the built environment to being part of the workflow. It was something you could change when needed and without hesitation. When you start to think of the robots as pieces you can move around, it activates a different kind of creativity. What if I dropped in a PCR machine and a plate imager? What else can I swap in there?

Fast forward to today and this system is ready for sale. RACs - Reconfigurable Automation Carts.

Each RAC has a dedicated robotic arm and a track for moving plates between units. There's quick connection points for aligning RACs together. There's a utility access port for hooking up electrical, air, and data lines and an optional HEPA filter if you need sterile air.

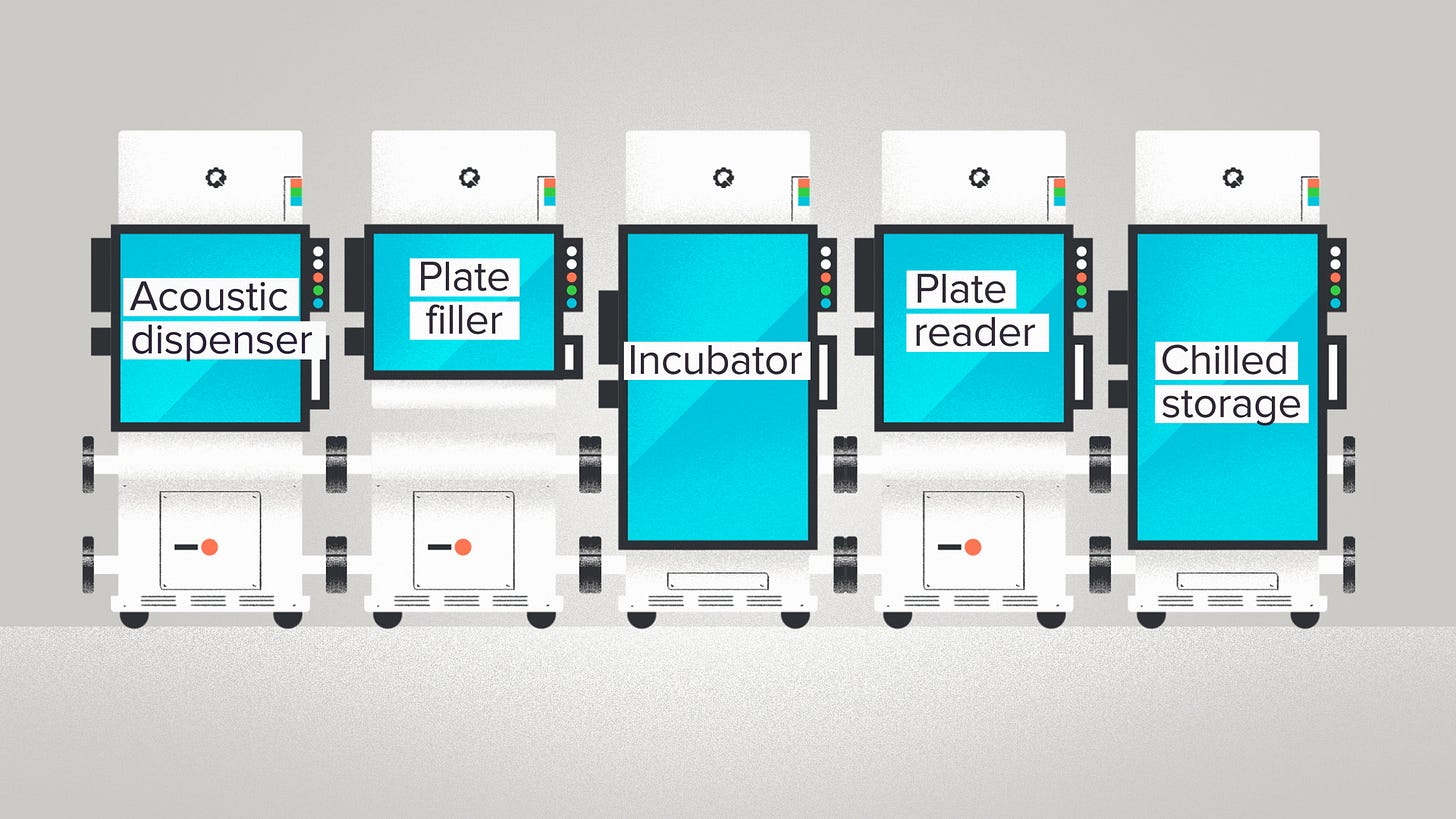

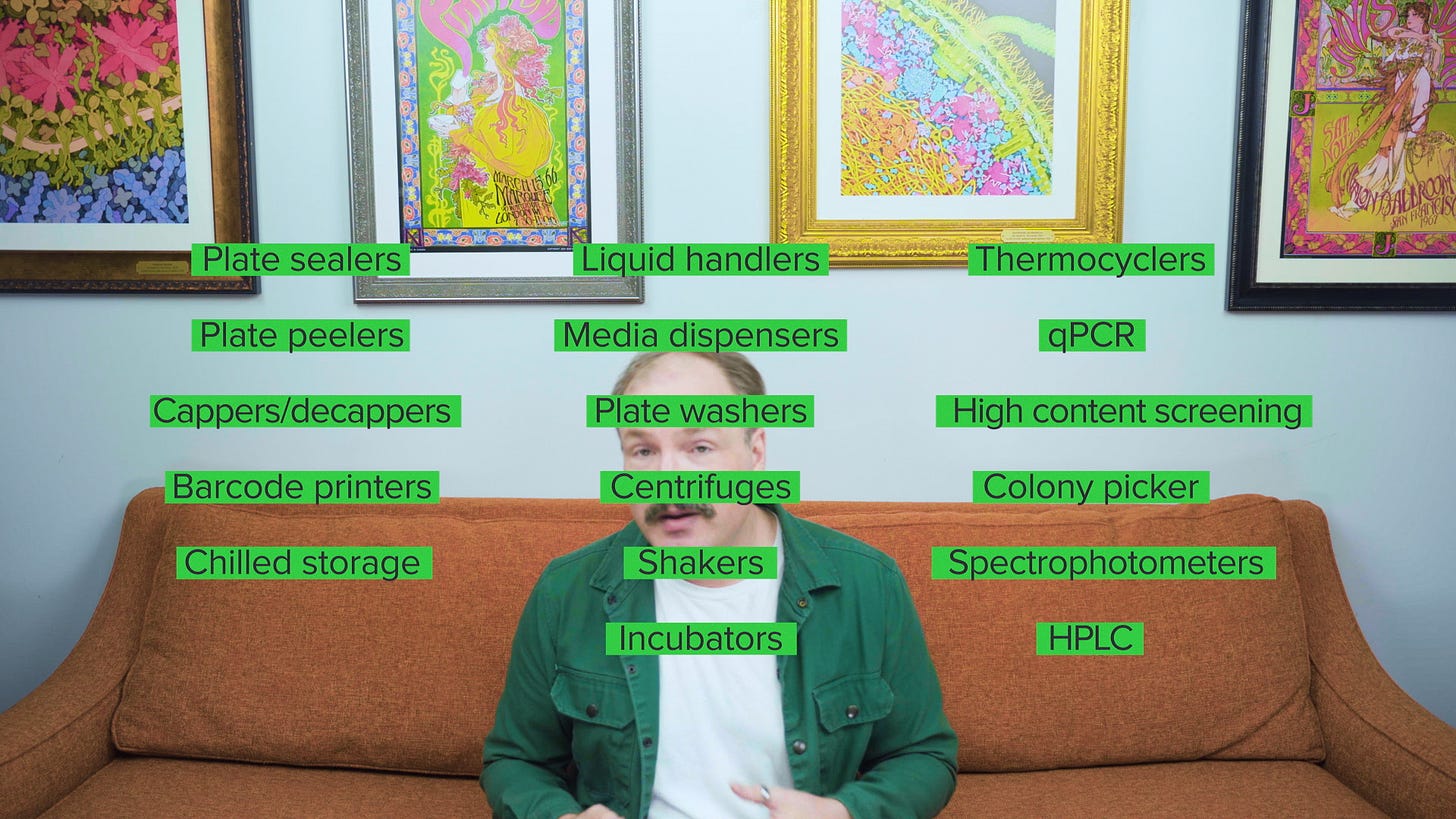

They come in different form factors to accommodate different machines that you might want to include in your experimental workflow. We've got them pre-configured for a lot of the off-the-shelf instrumentation that people already use.

Liquid handlers. Plate sealers and unsealers. Shakers. Centrifuges. PCR machines. Plate readers and imagers. Pretty much anything you'd commonly see in a modern bio lab. And if you use custom equipment, most of the time we can box it up and RAC it.

So what can you build with these RACs?

Maybe you're prepping samples for next-gen DNA sequencing. Pop together a plate peeler, liquid handler, centrifuge, and some chilled storage.

Maybe you're measuring viral vector titers for gene therapy. That's a plate filler, incubator, pipetting robot and a qPCR machine.

Maybe you're doing some chemical genetics: treating a cell line with a drug library and collecting high-dimensional data for an AI model. You'll need an acoustic liquid handler, incubator, shaker, a pipetting robot to prep for RNA seq, a plate reader for gene reporter assays, an imager for cell painting, etc. etc.

The RACs have matured a lot since back when they first blew my mind. Now they come with web-based automation control software. Remote support to catch and correct errors. You can stand up a new system quickly and reconfigure it quickly when your experimental needs change.

For a lot of users, that's going to be the bottom line. You want to generate a lot of biological data and you need to get your automation platform working fast. You don't want to spend months trying to plan out the perfect setup in advance, because you know that biotech R&D is going to surprise you anyway. Maybe you find out there's a bottleneck in your workflow around a particular machine. Your plates aren't getting loaded fast enough? Ka-chunk - Add another plate peeler to the line. This is a simple thing conceptually. But you might not even think to try it in a traditional automation setup where the robots are fixed in place and slow to change.

The thing that really sparks joy for me about these RACs is the way they open up new ways of thinking about laboratory automation. It's not just an efficiency unlock, it's a creativity unlock. There's this aha moment when you realize you can build lab automation from modular parts and the space of possibilities suddenly gets bigger.

You go from heavy, fixed installations to light, modular carts. You go from stand-alone benchtop robotics to integrated, fully automated workflows. You go from robots just sitting there and humans moving around them to humans and robots moving together.

Apologies - an earier version of this video had audio sync issues. Now corrected!