Lab Automation & Human-Robot Relations

Will we go to war with the machines? Will the robots replace us?

I don't know. I'm not here to predict the future. I'm here to get your biotech R&D program running more efficiently and that means making peace with the robots to get the most from lab automation.

Transcript

The number one mistake that people make when they think about lab automation is they frame it as an opposition between humans and robots. There's a task that needs to be done. Should a human do it or should a robot do it? Which one is faster? Which one is smarter?

The problem with this either/or thinking is that it exactly misses the point of a successful biotech R&D program - the human-robot relations.

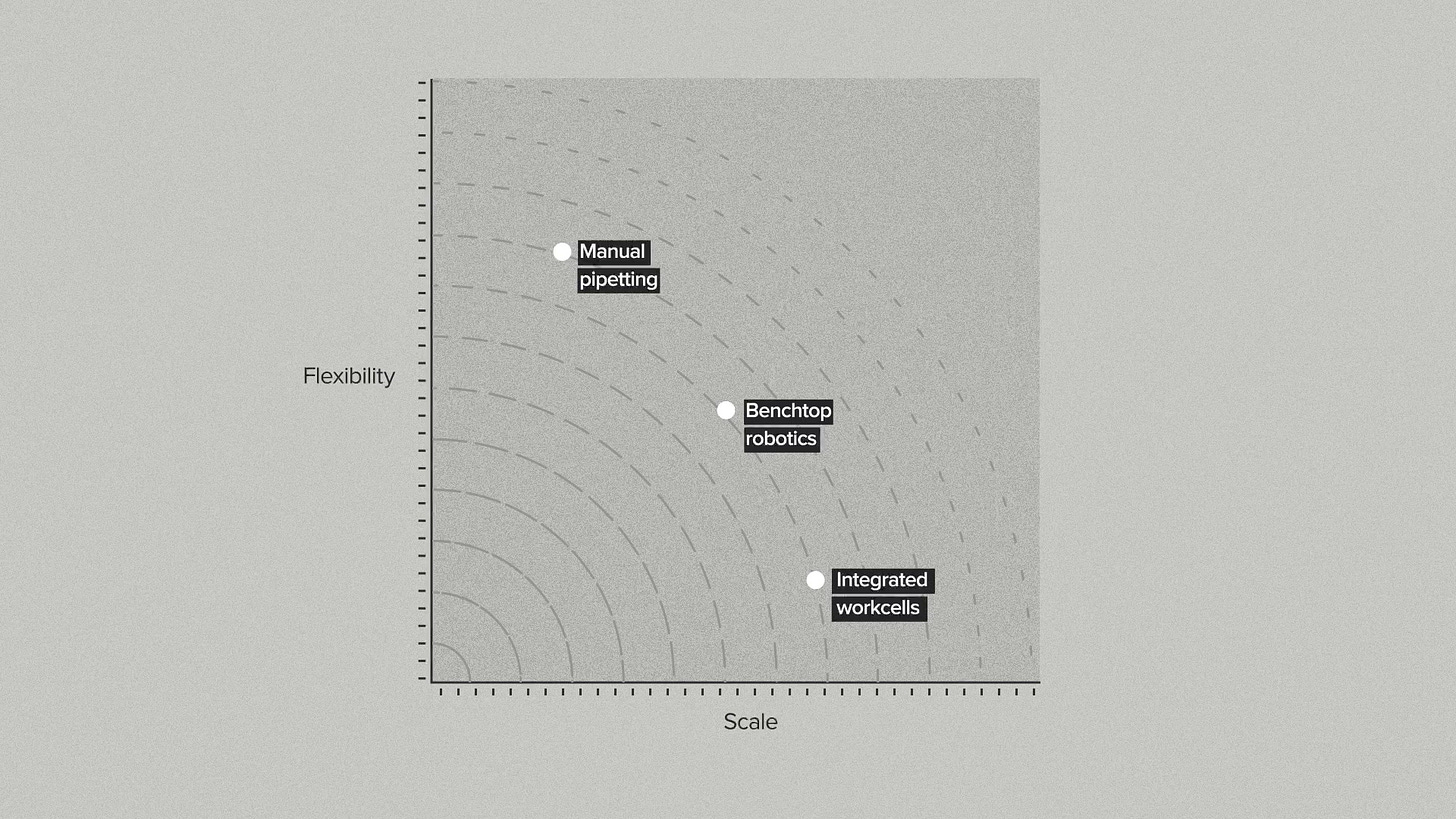

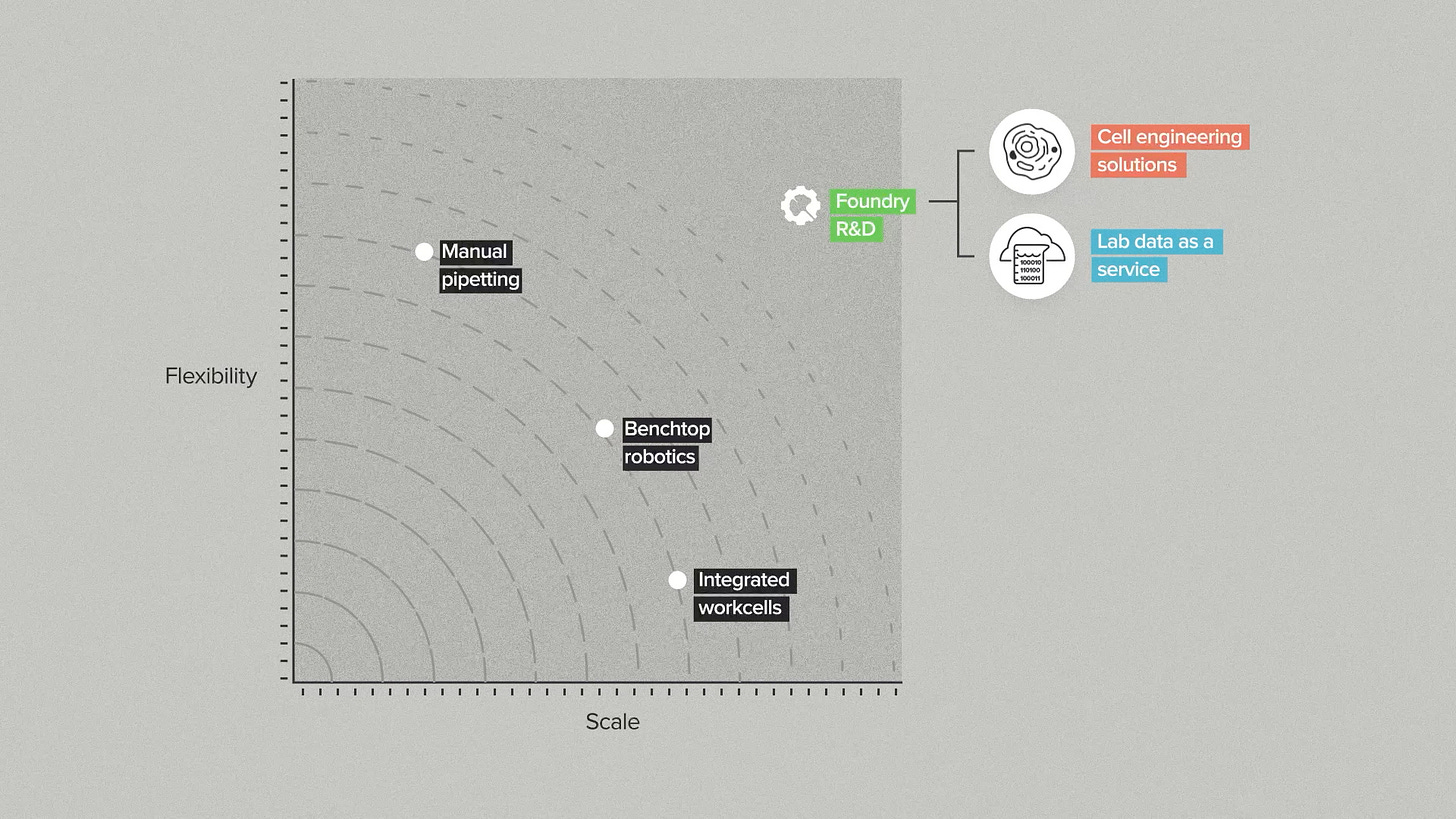

A better framework is to say that it's always a human doing the task and the robot is the tool they're doing it with. The human chooses the right type of automation depending on the flexibility and scale that the project requires.

Here at Ginkgo Bioworks, we use lab automation extensively to support the biotech R&D programs of our customers. You name the robot for moving around liquids in a biology lab, we've probably got one, plus a lot of custom hardware besides. It makes for a very complex looking shop floor. But I've found you can pretty quickly get a sense for the big picture of automation if you focus on the flexibility and scale needs for each job.

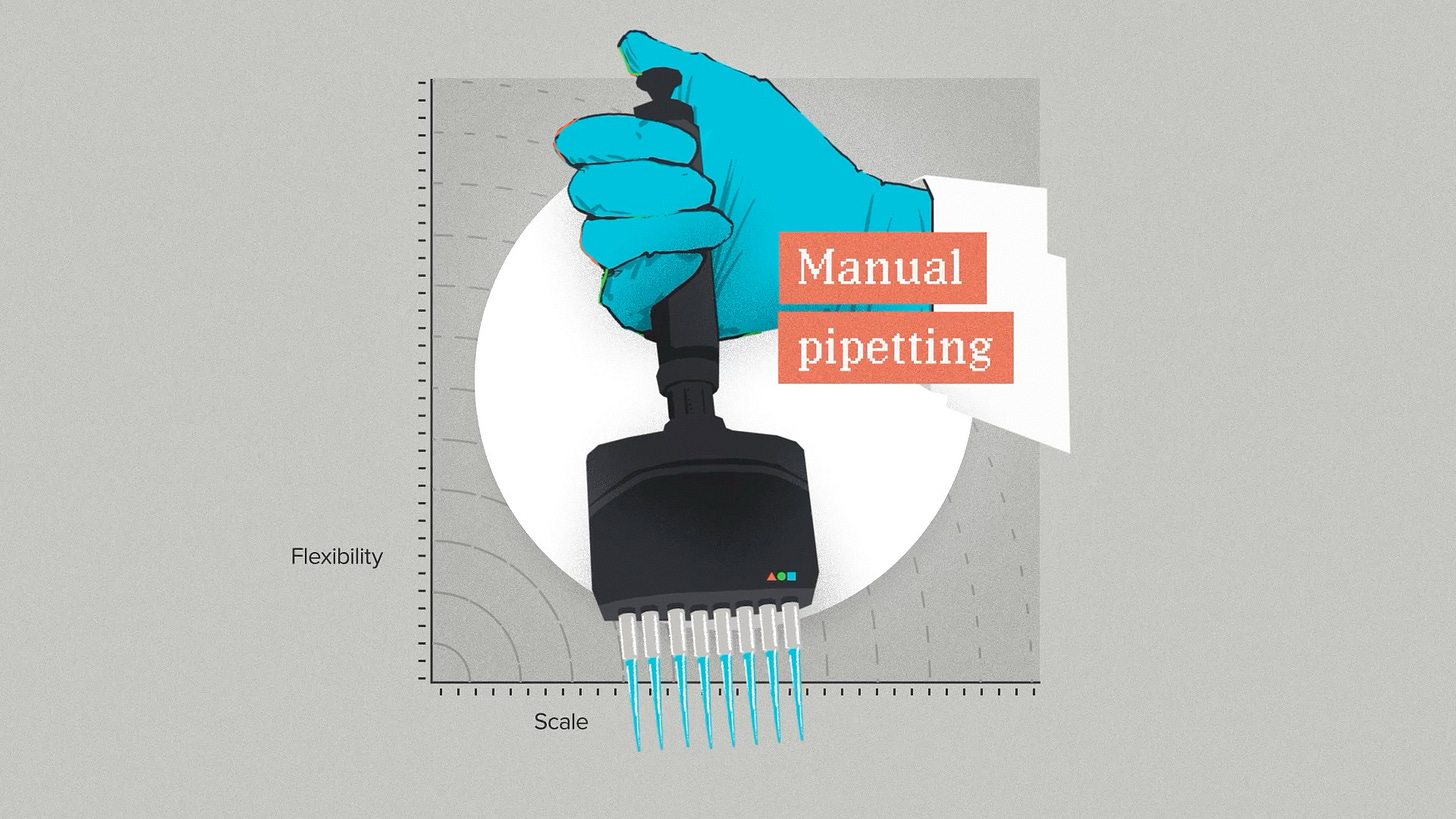

On the flexibility side, you have manual pipetting. This is how most biotech R&D is done in most places. Nothing against the human hand. These things can do anything you need. They can carve Michaelangelo's David. Well, mine can't, but you get the idea. This flexibility comes at the cost of scale. Manual pipetting just can't generate data at the scale you need for serious biotech R&D.

As for the human-robot relations, in this case the robot is just a plunger with a plastic tip. But we still shouldn't take it for granted. The flexibility of manual pipetting didn't come for free. Human scientists undergo years of training to use those things well. We should expect more complex tools will take at least as long to master.

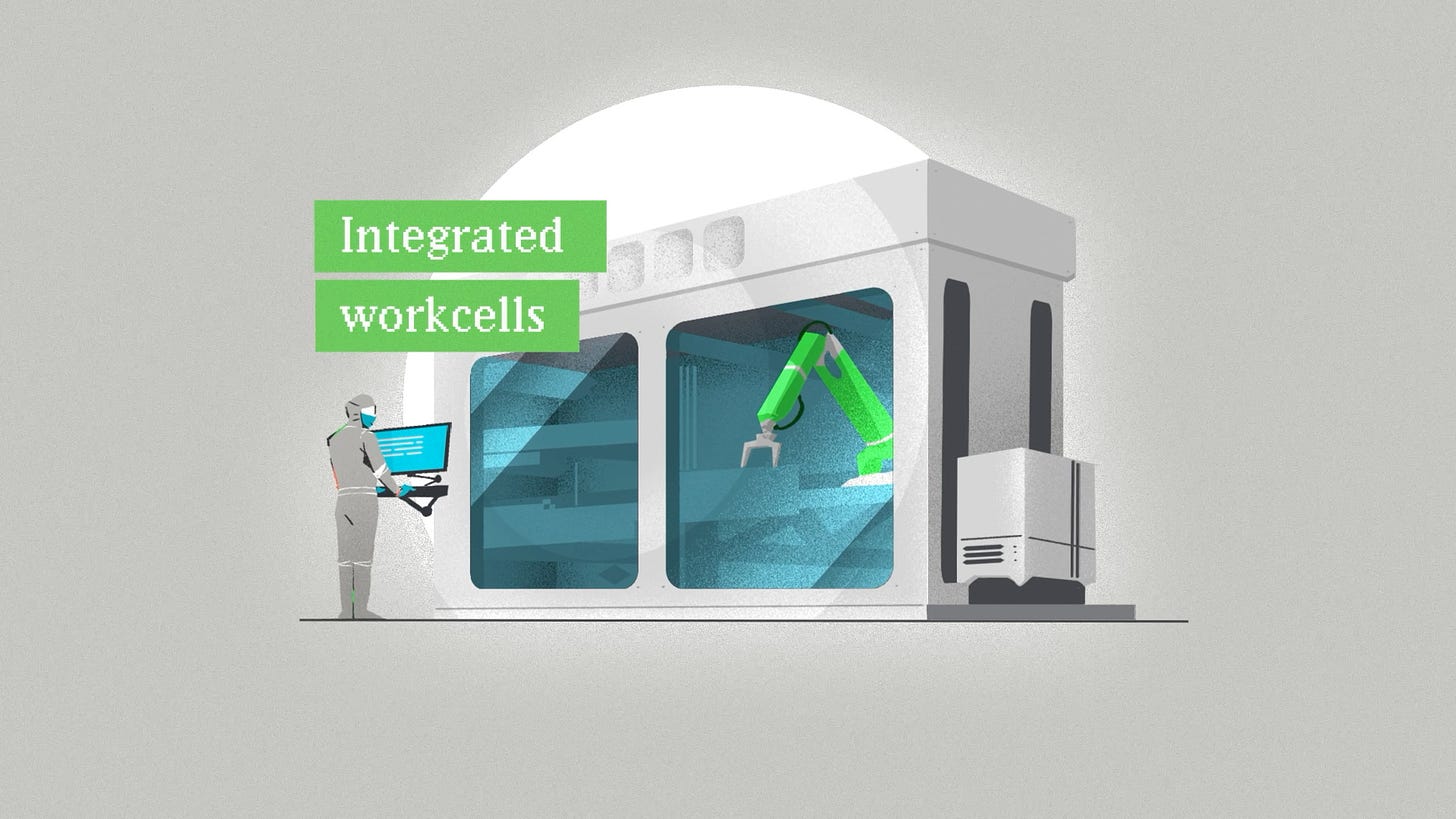

On the scale side, you have integrated workcells. These are gigantic systems that can automate every stage of a biotech R&D workflow. If you need to do one experiment a million times, this is your solution. One drug screen. One cell-based assay. One omics workflow. The scale of these systems comes at the cost of flexibility because most of the hardware is purpose built. The human-robot relations are managed by the engineers that build these systems, often taking years and millions of dollars.

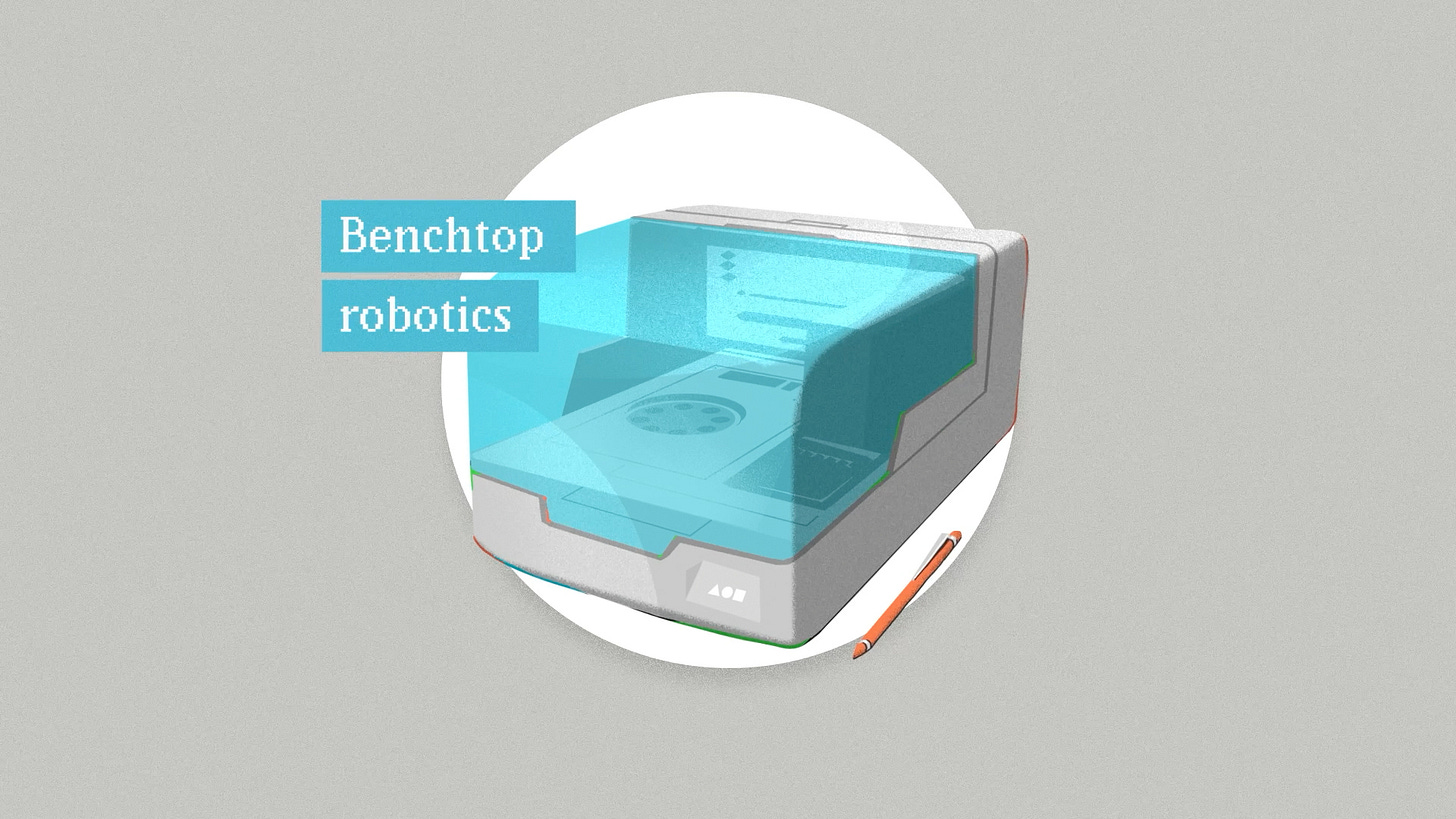

In between you have benchtop robotics. This is what most people mean when they say they use lab automation. Think about a liquid-handling robot that fills up 384-well plates with media. Or maybe it's an auto-sampler that collects cells from those same wells to feed them through a flow cytometer.

The quintessential experience is you walk up to the machine, load on some samples, wait around for them to finish, maybe check your phone, then unload the samples when they're done.

For most biologists, benchtop robotics is your first human-robot relationship and sometimes it breaks your heart. Unlike manual pipetting, you haven't had years of training to use this thing. Unlike a dedicated workcell, an engineering team didn't install a complete workflow. You've got to set it up. Learn the commands. Babysit it. Fix the errors. Clean up the waste streams. And the payoff, once you've learned how to use it well, is moderate flexibility and moderate scale.

But what if you want more than that?

Well, you can use the Ginkgo foundry, of course. We have the scale and the flexibility to generate the data your R&D program craves. DNA assembly and transformation. Genome resequencing. RNAseq. Metabolomics. Proteomics. Cell-based assays. We can do super targeted fee-for-service datasets in things like antibody developability or enzyme engineering. Or we can do complete cell engineering solutions for applications like gene therapy, cell therapy or functional genomics for target discovery.

This is possible because we've invested heavily in automation infrastructure. We've got the benchtop robotics, the dedicated workcells, and the human hands working together. We've also built out a significant internal platform of custom robotics and the software to run them.

But, I think, the secret sauce is the human-robot relations. It's a two-way street. A high performing foundry is not just about buying robots and giving them jobs that used to be done by humans. The automation engineers have to build a platform that works for the scientists. The scientists have to change the way they work and learn to use those tools effectively.

That same sense of mastery and control that you get after years of using a manual pipette. It's possible to bring that to a foundry-scale automation platform. But only with years of investment. The human-robot relationship isn't something you can buy out of the box. But it is something you can access immediately if you partner with Ginkgo for your R&D program, or if you buy data from us on a fee-for-service model.

The Ginkgo foundry is, if you like, a gigantic robot and you're the human user. You choose to work with us when you need exceptional flexibility and scale.