Bioproduction Scales in Powers of Ten

Biology can arrange the individual atoms of a molecule and biology can grow to fill a swimming-pool sized bioreactor. Today we're talking about some foundry tech that we use to engineer cells for bioproduction, organized from the microscopic to the gigantic.

Transcript

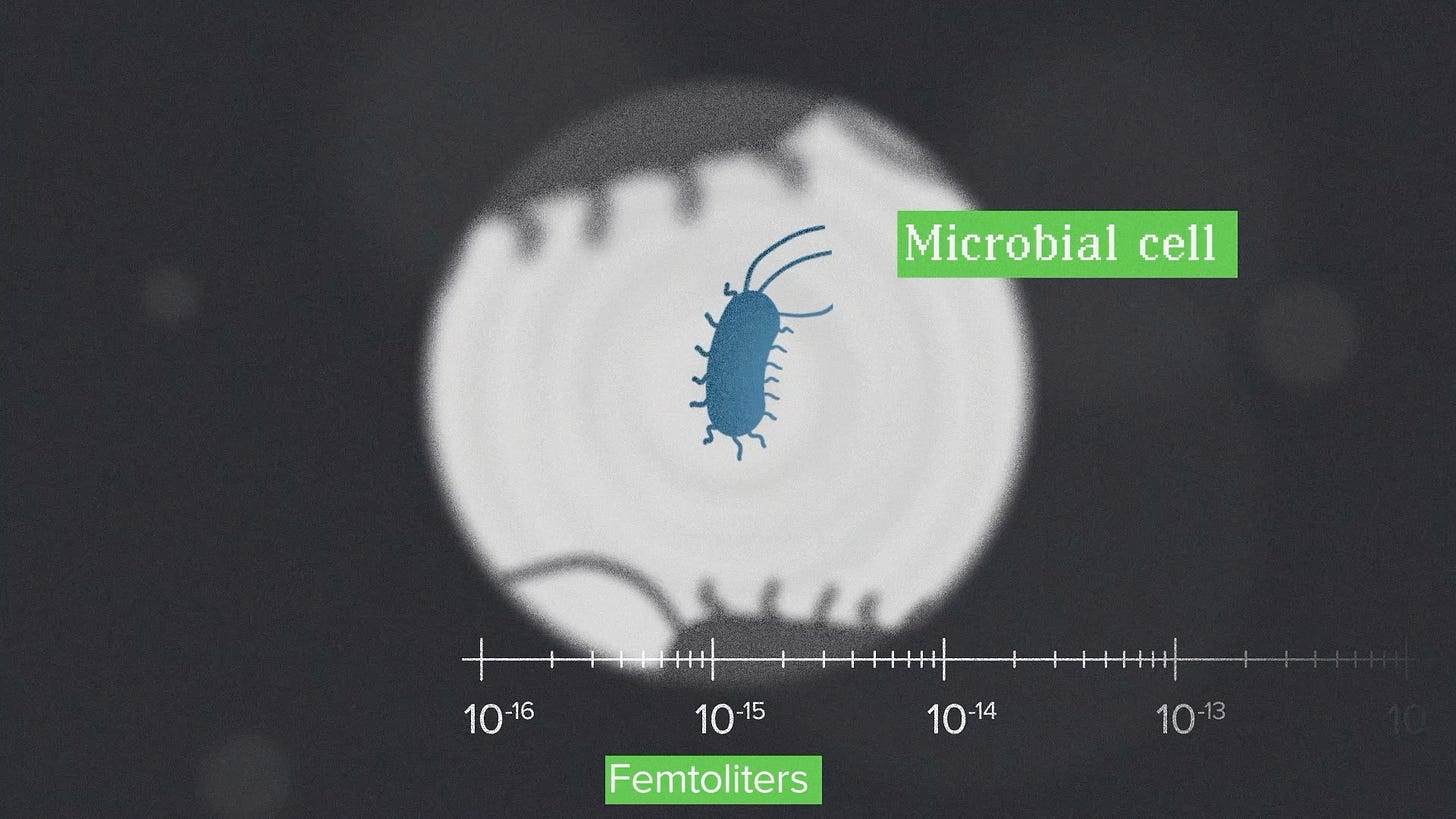

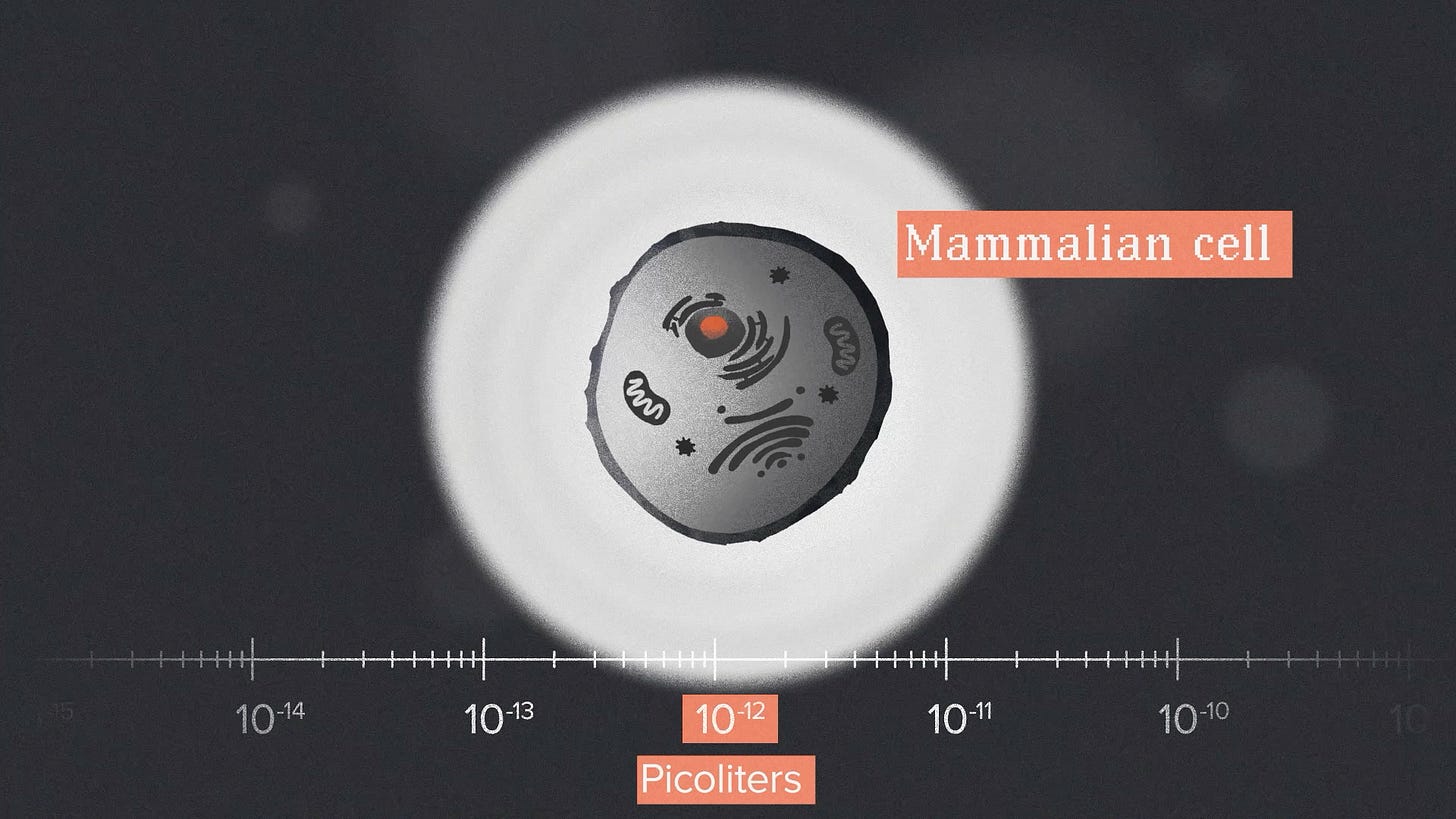

The journey of every bioprocess begins with a single cell.

Here at Ginkgo Bioworks we work with both microbial and mammalian cells. A typical microbe, like a yeast or bacterium, is a few femtoliters in volume. That's 10 to the negative 15th power or one quadrillionth of a liter. A typical mammalian cell is 100 or 1000 times larger, with a volume of a few picoliters.

Cell programming is what we do at Ginkgo and what we deliver to our customers. We make the cells that you need to make your products. We've engineered cells for food proteins, functional enzymes or fine chemicals. For biopharma applications a cell might produce a biologic or a protein drug, a vaccine ingredient or a gene therapy.

Engineering biology for a bioprocess means working at a different scales. We typically want to scale down our cell programming operations to make them as fast and cheap as possible. We try lots of designs, generate data, and find the most productive candidates. Then we validate those candidates at progressively larger scales until we reach the final bioprocess. We don't need to test every strain at every scale, but we want a range of technologies, big and small, that we can deploy as the project requires.

The very smallest scale at which we can run a bioprocess is the nanoliter scale. This is with a piece technology unique to Ginkgo called EncapS for Encapsulation and Screening. With EncapS, we can package cells into microscopic hydrogel beads. Although the beads are very small, they have all the essentials. There's room to grow, media to consume, and they capture any fermentation products the cells put out. We then measure these products using fluorescence to sort out the top performers. The advantage of working at the very small scale is the sheer number of samples we can screen - up to 100,000 in a single run.

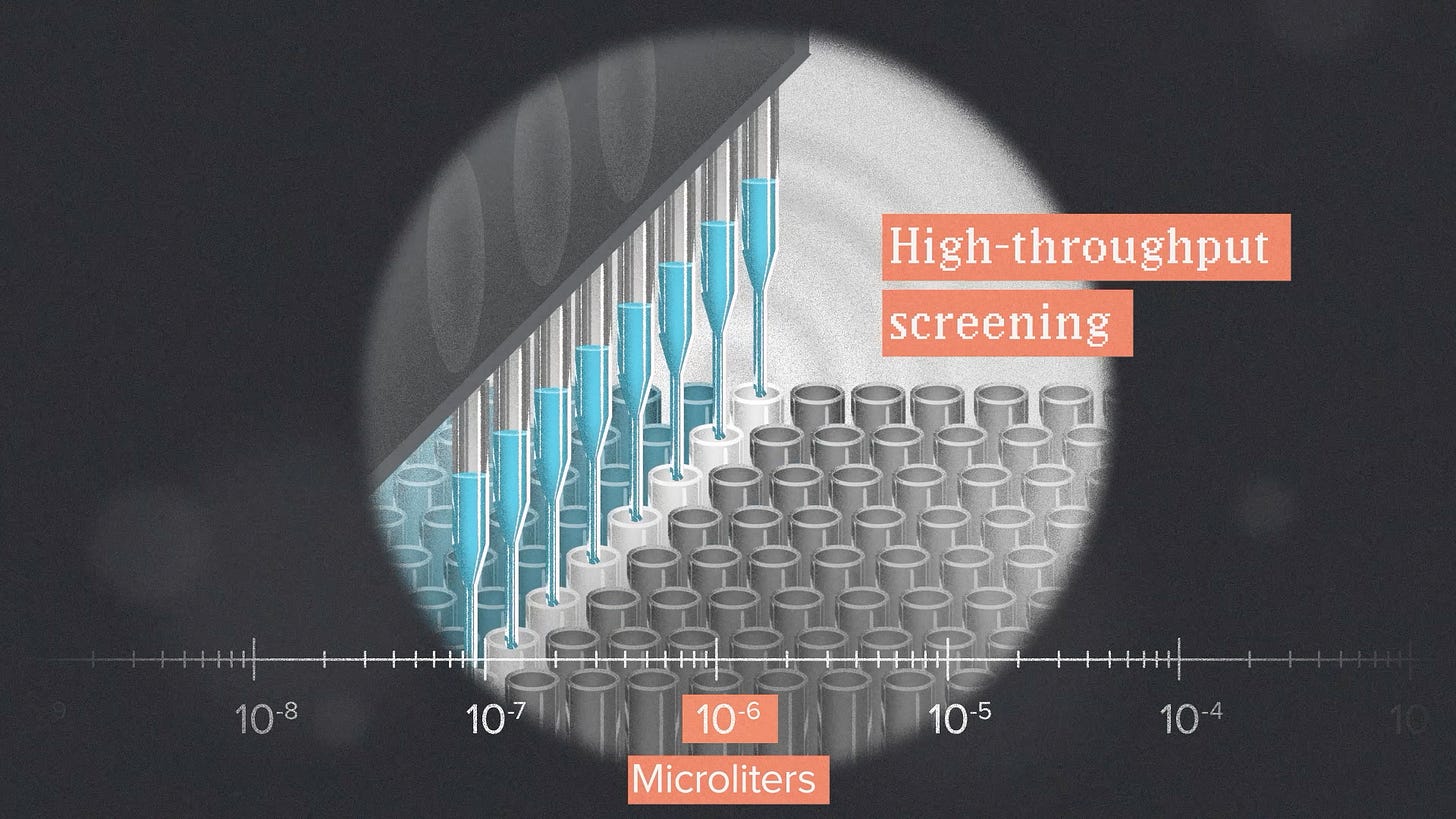

The next step up in scale is probably the most familiar to the biologists out there. At the microliter scale, we're handling volumes from about the size of a teardrop to a teaspoon. Most laboratory biology has traditionally been done at the microliter scale, because this is the size when samples can be seen by the human eye and moved with the human hand.

At Ginkgo, we're all about enhancing those human hands with automation. In a typical high-throughput screen, we might move 1000 samples of 20 microliters each, arrayed on standard microplates. An automation workcell will take the plates through a series of operations to grow the cells, transform them with engineered DNA, and measure their productivity.

The microliter scale offers the widest range of techniques for transforming, characterizing and measuring cells. For most of my career as an academic scientist, it was also where the story ended. When you're doing basic research, you can usually learn everything you want to learn about a cell by doing experiments at the microliter scale. But on the journey to real bioproduction, you're still only halfway done.

The first true bioreactors that we work with are usually Ambr® 250 arrays. The 250 refers to the volume of 250 milliliters or one fourth of a liter. These are about the size of a soda can, big enough that you can hook up the inputs, outputs and sensors that you need for active process control. We can monitor the pH, oxygen levels and nutrient composition like you would in a much larger process.

Bioreactor arrays are big enough to effectively simulate a scaled-up bioprocess, but still small enough that we can operate them in sets of 12 or 24. That means we can continue to optimize across different cell lines and different process conditions. The liter scale is the moment of truth for many bioprocesses, the step when we see performance data under conditions that closely resemble what a fully scaled process might look like.

Once we've got those parameters locked in, it's time to move the process out of the laboratory and into a more industrial setting. We have pilot scale fermenters with volumes of 30 liters, 300 liters or 3000 liters. Bigger than that, we'll tech-transfer the process to your facility, to your contract manufacturer, or to a partner that we can recommend.

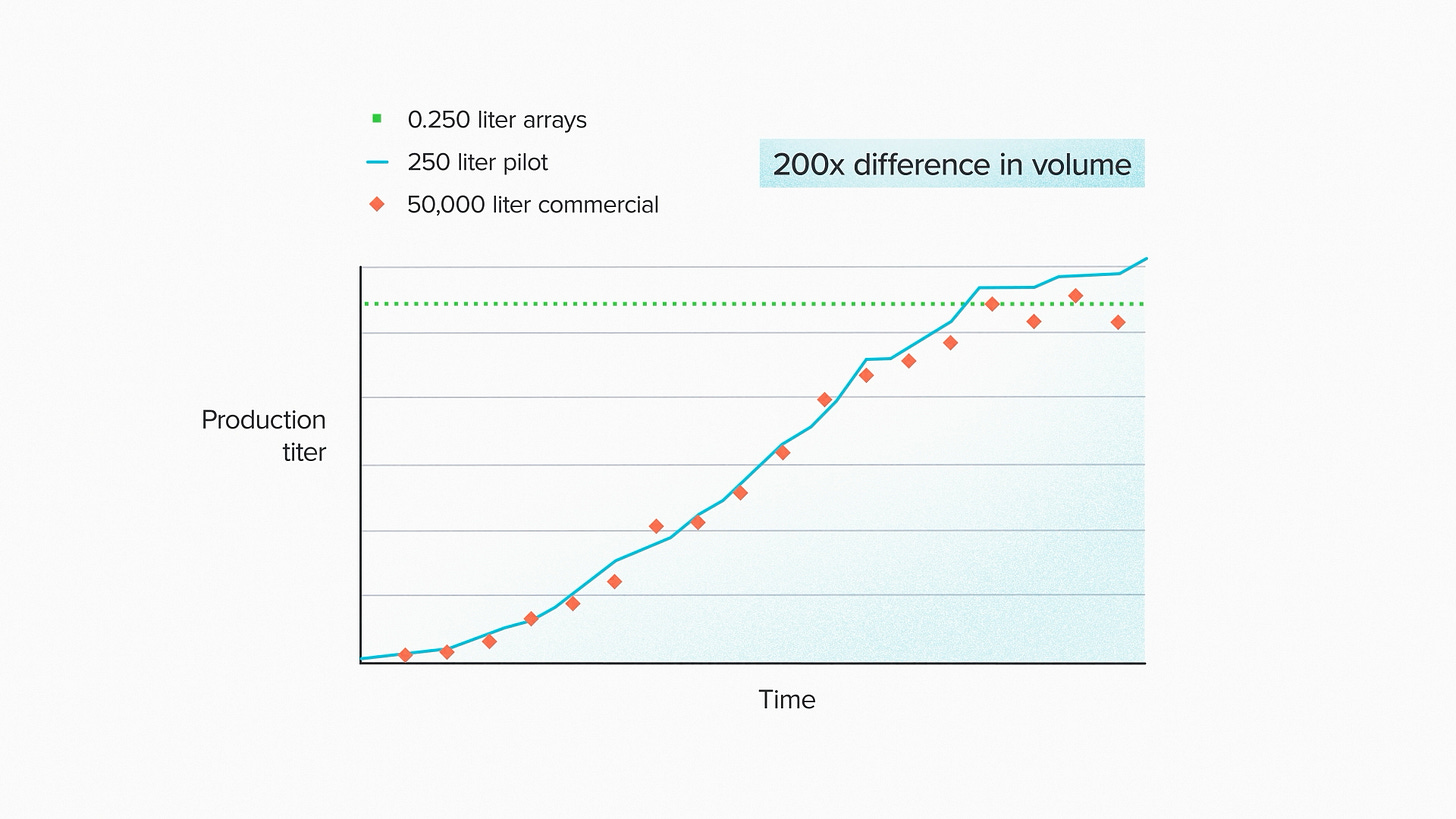

Here's an example of the final steps of a successful bioproduction journey. We used the Ambr® 250 arrays to optimize a bioprocess. We measured the product titer, first in a 250 liter pilot reactor, then again in the 50,000 liter reactor for true commercial scale. That's a 200x difference in volume, but the titer was consistent across all three systems.

From a 50 femtoliter living cell to a 50,000 liter bioreactor. That's about 18 powers of ten. For the cells, it's not really a big deal. It only takes a few days of exponential growth for them to fill up all that space. For the human engineers at Ginkgo, what makes it work is the ability to think and work across many different scales. We can engineer, screen and select lots of individual cells to choose the very best performers. Then we take them end-to-end to perform on the big stage.